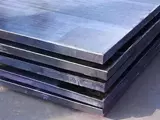

Steel Casing is a common term used in the steel industry to describe one of the main products of steel production. Steel Casing is a thin steel sheet made of either cold rolled or hot rolled steel, which is then covered with a protective coating, typically zinc or galvanized steel, to prevent oxidation and corrosion. Steel casing is widely used in the construction industry for a variety of applications including roofing, wall cladding and other structural and decorative elements.

Steel casing is also known as cold rolled steel or hot rolled steel, depending on the method used to produce it. Cold rolled steel is formed by passing a hot, heated steel sheet through rollers with a lower roll temperature than the temperature of the heated steel, resulting in a thinner steel sheet that has undergone less thermal stress. Hot rolled steel is cold-formed from heated steel and quickly passed through high pressure rollers to force it into the desired shape.

The protective coating on steel casing is designed to prevent oxidation and corrosion of the steel sheet. The coating is usually applied as a continuous, uniform layer on the entire surface of the steel sheet and can be applied using different methods, depending on the application requirements. It can be applied by either dipping the steel sheet into a solution containing the protective coating material, or by spraying the coating onto the surface. There are several types of protective coatings available, such as galvanized steel, zinc-coated steel, aluminum-coated steel, stainless steel, and epoxy-coated steel.

Steel casing is an ideal choice for a variety of applications as it is highly durable, strong and lightweight. It has excellent corrosion resistance and is resistant to most chemical and environmental conditions, making it an ideal choice for applications requiring a protective yet cost-effective cover. Steel casing is also highly fire-resistant, making it a great choice for applications requiring a fire-rated material.

Steel casing is also easy to install and can be cut and formed into any desired shape or size. It is a versatile material that can be used for a variety of purposes, such as roofing and wall cladding, structural applications, and even decorative elements. Steel casing can also be used to add strength and integrity to a structure as it is much stronger than traditional woods and metals, helping to minimize structural defects.

Steel casing is a cost-effective and versatile option for many applications and is widely used in the steel industry. It is an ideal choice for projects requiring an attractive and protective covering that is also strong and lightweight.