Cutting Quantity and Tool Selection Skills in CNC Programming

Computer Numerical Control (CNC) programming is used in modern manufacturing to produce parts accurately and quickly. This is done by cutting parts from raw materials using cutting tools and CNC machine tools. The success of the CNC programming depends on the selection of appropriate cutting parameters, cutting tool and cutting quantity. These elements are interdependent and must be in harmony to effectively produce the part.

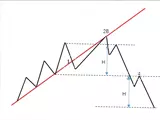

The selection of the cutting method, cutting speed, feed rate, depth of cut and cutting tool geometry determines the cutting parameters that are used in CNC programming. The cutting tool is also a key element in successful CNC programming. The cutting tool must be compatible with the type of material to be machined, the cutting parameters and the cutting speed. This ensures that the tool is able to machine the material without damage. The cutting tool selection also affects the cutting quantity, as it affects the cutting forces and thus the amount of material that can be cut per unit time.

The cutting quantity also plays an important role in successful CNC programming. Increasing the cutting quantity can reduce machining time and increase the productivity of the part being manufactured. However, this has to be done in a balanced way, as increasing the cutting quantity too much can lead to excessive cutting forces and tool wear. The cutting speed and the feed rate of the cutting tool also have an impact on the cutting quantity - increasing the cutting speed leads to higher cutting forces which leads to more material being cut.

Finally, the choice of cutting tools and cutting quantity will have a direct effect on the quality of the machined parts. High quality parts require careful consideration of the cutting parameters as well as the cutting tools and cutting quantity. The cutting tool must be able to cope with the cutting speed, feed rate and cutting force, while allowing for a good surface finish of the part. The ideal cutting tool selection should result in less tool wear, increased tool life and improved surface quality.

In summary, successful CNC programming requires careful consideration of the cutting parameters, cutting tool selection and cutting quantity. The cutting parameters will determine the cutting speed and feed rate, while the cutting tool selection must be compatible with the material, cutting parameters and cutting speed. Finally, the cutting quantity must be carefully balanced in order to reduce machining time and achieve a good surface finish on the part.