?

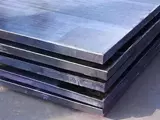

The Standard AS/NZS 1449/1.5-1991 Carbon Steels and Carbon Manganese Steels, Slab, Sheet, and Strip - Finished Analysis Tolerances specifies the allowable tolerances for the finished analysis of carbon steels and carbon-manganese steels slab, sheet and strip.

The standard covers the conditions of commercial manufacturing and applies to material of established nominal composition. It specifies limits for individual elements, impurities and maximum total impurities and limits of sulfur, phosphorus, and nitrogen.

The standard is intended to promote understanding between buyers and sellers as to the composition of carbon and carbon manganese steels slab, sheet and strip, delivered in the heat treated and finished condition.

The standard covers four finished hardnesses, from which the user may select one of the following: Annealed, Normalized, Quenched and Tempered, or By Combination hardnesses. This standard is applicable only to those steels that have the full specified range of low, medium and high carbon contents.

The table of maximum allowed tolerances for the finished analysis of Carbon Steels and Carbon Manganese Steels Slab, Sheet, and Strip are as follows:

• Carbon – max 0.01%

• Silicon – max 0.50%

• Manganese – max 1.20%

• Phosphorus – max 0.25%

• Sulphur – max 0.25%

• Nickel – max 0.50%

• Chromium – max 0.30%

• Copper – max 0.50%

• Molybdenum – max 0.30%

• Sulphide – max 0.50%

• Nitrogen – max 0.05%

• Aluminum – max 0.40%

• Titanium, Vanadium, and Columbium – max 0.10% each

• Boron – max 0.50%

• Various minor elements – max 1.60%

• Total impurities – max 2.20%

These tolerances are applicable when maximum chemical compositions are within the specified limits of the standard and have been determined by chemical analysis and statistical compilation.

AS/NZS 1449/1.5-1991 Carbon Steels and Carbon Manganese Steels, Slab, Sheet and Strip – Finished Analysis Tolerances are designed to produce uniformity and consistency in chemical composition and finish. The primary aim is to help ensure that customers receive products which meet specified chemical composition and performance requirements. The secondary aim is to reduce the production costs by increasing efficient use of resources, minimizing testing requirements of the chemical composition in the finished product and safely operating industrial machinery. Finally, the standard provides legal implications in case of an agreement or dispute regarding the chemical compositions of the materials.