The Application of H Beam in Tunnel Engineering

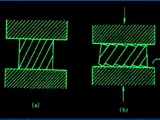

Tunnel engineering is an advanced form of underground construction, which is crucial to effective transportation, urban development and the development of infrastructure. As the main supporting structure of the tunnel, H beam steel is the most common material used in tunnel engineering. H beam steel has excellent properties, such as high strength, good plasticity, corrosion resistance, convenient installation, and long life. Therefore, H beam steel is widely used in tunnel engineering and is also the most common type of steel used in tunnels.

The H beam steel has a strong ability to carry horizontal and vertical loads, making it suitable for tunnel engineering. Because the span of tunnel construction is generally large, it requires H beam steel with high strength and good seismic performance. In addition, due to the long life of tunnels, anti-corrosion properties is also an important factor that should be taken into consideration when selecting H beam steel for tunnel engineering.

In tunnel engineering, H beam steel also has certain advantages in terms of installation and construction. In particular, the installation of various mechanical and electrical systems and the construction of other environmental and safety facilities are very convenient. In particular, H beam steel can reduce the weight of the entire structure by reducing the area of the opening by round or other means. This can help improve the safety and stability of the structure, reduce the cost of maintenance, and prolong the service life of the tunnel.

In addition, the H beam steel also has advantages in terms of fireproof performance. Because of its high fireproof performance, it is widely used in special buildings, such as high-speed rail tunnels and underground fire protection projects, so as to ensure the safety of the whole tunnel engineering.

Overall, H beam steel is an indispensable material in tunnel engineering. In addition to having excellent properties, it also has the advantages of convenient installation and construction, reducing structure weight, and improving safety and fireproofing performance. Nowadays, H beam steel has become the mainstream material for tunnel engineering, widely used in various types of tunnels.