The use of platinum group metals (PGMs) has increased steadily over the past decade, fueled in part by improvements in technology and societys shifting energy needs. The platonic metal, palladium, and its cousins gold, rhodium, iridium, and ruthenium, can be found in a variety of applications, from catalytic converters to electronic components to medical implants and surgical instruments.

One of the most exciting new applications for PGMs is found in the form of sponge platinum. Also known as platinum sponge, this new form of platinum is being used in industrial and automotive applications, where it has the capabilities to enhance fuel efficiency and reduce emissions.

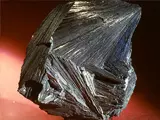

Sponge platinum is a special form of platinum created through a process of treating the material with chemicals to form small, porous platinum particles. These particles have a much larger surface area than standard platinum pellets, which increases their absorption and catalytic ability. As a result, the use of sponge platinum in a vehicles catalytic converter can increase the efficiency of the converter and reduce the emission of hazardous gases from the vehicle. In addition, sponge platinum has been found to improve the efficiency of diesel engines, by increasing the rate at which diesel fuel is burned.

Sponge platinum is also being used as a catalyst for fuel cell reactions. In these reactions, a combustible fuel is mixed with an electrolyte, such as water, and an electrochemical reaction occurs, resulting in the production of electricity. The addition of sponge platinum increases the surface area available for the reaction, resulting in an increased efficiency of the fuel cell.

Sponge platinum has some additional benefits as well. For example, because of its porous nature, the material can absorb small amounts of other substances, such as chemicals, herbs, and nutrients. This makes it a useful tool in the medical field, where it is being used to deliver medication directly to specific parts of the body. It also has potential applications in industrial processes, where it can be used to bind particles of different size and shape together.

The advantages of sponge platinum have led to increased interest in the material, and it is expected that its use will continue to grow in industry and other areas. As technology continues to advance, and new applications for the material are discovered, the potential for sponge platinum will continue to grow.