The Relationship between Determining the Dimensions of H-shaped Steel Billets and Different Processes

Introduction

H-shaped steel billet is a steel product which is manufactured in the shape of an H. It is used in a variety of industrial applications, such as in the construction of bridges, pipes, railway lines, and other steel structures. The dimensions of H-shaped steel billet need to be accurately determined so that it can be used efficiently in the desired application. The dimensions of the steel billet are strongly influenced by the process used in its manufacture. This article will explore the relationship between determining the dimensions of H-shaped steel billet and different processes.

Rolling Process

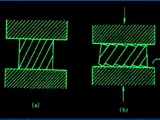

The rolling process is the most common manufacturing process used to produce H-shaped steel billets. During the rolling process, the billets are compressed between two large rollers in order to deform them. The deformation of the billets changes the dimensions of the material and it can be used to accurately control the dimensions of the finished product. The rolling process can be used to create H-shape steel billets with a variety of dimensions such as thickness, width, and length.

Molding Process

The molding process is another method used to produce H-shaped steel billets. During the molding process, molten steel is poured into a mold in order to shape the material. The dimensions of the steel billet can be precisely controlled by manipulating the size of the mold. The molding process can be used to create H-shaped steel billets with highly accurate dimensions.

Extrusion Process

The extrusion process is another manufacturing method used to produce H-shaped steel billets. During the extrusion process, molten steel is forced through a die in order to shape the material. The die can be used to control the dimensions of the finished product. The extrusion process can be used to create H-shaped steel billets with high precision dimensions.

Conclusion

H-shaped steel billet is a steel product which is commonly used in a variety of industrial applications. The dimensions of the steel billet are strongly influenced by the process used in its manufacture. Rolling, molding and extrusion are three common processes used to produce H-shaped steel billets. The dimensions of the billets can be accurately controlled by manipulating the size of the rollers or dies in each process. Therefore, understanding the relationship between determining the dimensions of H-shaped steel billet and different processes can be extremely beneficial when manufacturing steel products.