Application of H-Shape Steel in Industrial Steel Structure Components

Introduction

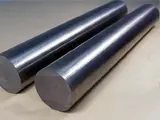

The H-shaped steel has been widely used as one of the main materials for industrial steel structure components. With its high strength and ability to form multiple shapes, H-shaped steel is a great choice for many applications, such as high-rise buildings and bridges. This paper aims to explain the advantages of H-shaped steel and discuss its usage and application in industrial steel structure components.

Advantages of H-Shape Steel

One of the major advantages of H-shaped steel is its strength. H-shaped steel has a higher strength-to-weight ratio than other structural steel shapes, making it a popular choice for high-rise buildings. In addition, it is also capable of carrying heavy loads since it does not easily buckle in the face of changing loads and can support forces along two directions. H-shaped steel also has excellent ductility, which allows it to be bent and twisted into many shapes, depending on what is needed for the particular application.

In addition to its strength and ductility, H-shaped steel can also be easily fabricated and machined. Since the material is cold-formed, it can be easily cut, drilled, and welded without the need for expensive production equipment. Furthermore, H-shaped steel is also corrosion-resistant, making it ideal for outdoor applications where it will be exposed to the elements. This also helps reduce maintenance costs as it is not necessary to periodically clean and coat the steel.

Application in Industrial Steel Structure Components

H-shaped steel has been widely used in many applications, such as to reinforce buildings, construct bridges and other structures, and build ships and automobiles. In industrial steel structure components, H-shaped steel can be used for columns, beams, trusses, and bracing.

For columns, H-shaped steel is commonly used to provide vertical support, especially in high-rise structures. The material is usually used in tapered or slim shapes to provide enhanced stability and load carrying capacity. Additionally, due to its high strength and ductility, H-shaped steel also makes an excellent choice for bracing. It can be bent and twisted into many shapes, giving greater flexibility in the design of the structure.

Furthermore, H-shaped steel is also an excellent choice for beams since it is able to support large loads and can span great distances. The shape of the beam can be adjusted according to the application, and the material is capable of resisting twisting and shearing. This makes H-shaped steel a great choice for trusses, which are important components in many steel structures.

Conclusion

In conclusion, H-shaped steel is a popular choice for industrial steel structure components due to its high strength, excellent ductility, and ability to be fabricated and machined. It is particularly suited for columns, beams, trusses, and bracing, and is a great choice for applications that require high load-bearing capacity or are exposed to harsh weather conditions. With its numerous advantages, H-shaped steel is an attractive choice for many applications.